1916

Download

Please wait a moment ...

Download

Please wait a moment ...

Delete

Do you really want to delete the data record?

Download

Please wait a moment ...

Download

Please wait a moment ...

Download

Please wait a moment ...

Crop for shopping cart

Please wait a moment ...

Set as main picture

Do you want to set this media object as main picture?

-

19 January 1916

-

The DMG plant at Marienfelde receives an order for twelve 300 hp / 221 kW six-cylinder diesel submarine engines. The first seven units of the MU 256 powerplant are delivered before the end of the year. Benz & Cie. is also hard at work on high-output diesel engines for use in submarines and supplies eight S6 Ln 450 hp / 331 kW six-cylinder units during the course of 1915 and 1916.

-

December 1916

-

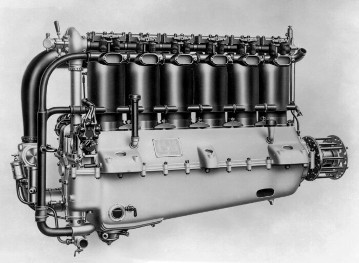

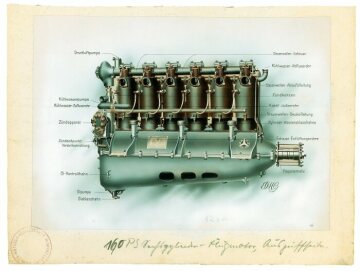

The Mercedes D IIIa aeroengine, a derivative of the D III, passes the modification test in Berlin-Adlershof. The D IIIa and predecessor, of which some 12,000 units were produced in all, is the most built German aeroengine of the First World War. Officially, by war's end it has the reputation of being the most proven German aeroengine next to the Bz IV.

Loading